Led by senior engineers from Carlisle and Amphenol, our

product development, engineering, quality, operations

and sales teams are focused on meeting and exceeding the

unique requirements of our customers.

By

benefiting from a wide selection of connectors and

components ready-made for patient monitoring system,

Orantech offers significant savings for the customers on

OEM projects.

From Design Input to Final Assembly

At Orantech, our OEM cable manufacturing process is built around precision, partnership, and compliance. From initial engineering consultation through tooling, prototyping, and full production, we manage every stage in-house to ensure quality, traceability, and speed.

Our Shenzhen-based facility is ISO 13485:2016 certified, FDA registered, and equipped with state-of-the-art testing labs to validate performance and safety at each step.

Key Stages of Our OEM Manufacturing Process:

- Design collaboration & technical consultation

- Prototype development & performance testing

- Compliance review (510(k), CE, ISO)

- Final assembly, labeling, and QC

Why OEMs Trust Orantech:

- Full in-house production control

- Scalable for low- to high-volume manufacturing

- Support for regulatory documentation and audits

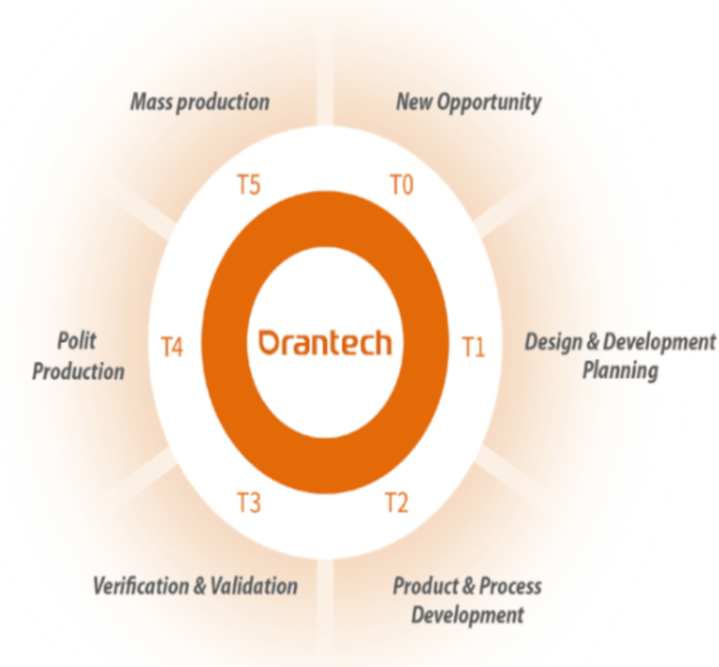

OEM/ODM Customized Service

Our collaborative process involves six phases for targeted production:

Six Phases

T0: New Opportunity

• Requirements Gathering

• Needs Analysis

& Assessment

• Stakeholder Alignment

• Quotation

T1: Design and Development Planning

• Verify Technical Specifications

• DFM

Review

• Stakeholder Alignment

•

Establish Specifications

• MVP Generated

T2: Product and Process Development

• Flow chart/PFMEA/SOP/QCP

• Prototype

•

DVT Plan (In-house/3rd Party)

• DOE &

PV Protocol (IQ/OQ/PQ)

• TMV Protocol

• Customer Approval

T3: Verification and Validation

• Equipment/Fixtures Qualification

•

Component Qualification (FAI)

• Component

Inspection Plan

• Report (DVT/TMV/PV/MVP)

• Customer Approval

T4: Production

• Training

• Assembly FAI

• Production

Approval

T5: Mass Production

• Ramp up Plan

• Change Control Management

(ECN/PCN)

• Cost Saving Proposal

•

Customer Approval

• Satisfaction Assurance

Development and design

Orantech works in partnership with its customers throughout the development process, bringing a breadth and depth of expertise and solutions to solve the most complex challenges. Orantech provides expert teams in design, engineering, quality, and project management to help you deliver innovative products to the marketplace.

- Electro-Mechanical Assemblies

- Connector, Contact and Cable Design

- Injection Molding, Over Molding and Insert Molding

- Mold Flow Analysis

- Testing and Verification

- Cleaning Requirements & Validation

- Product Qualification

- Labeling and Unique Device Identification

Manufacturing solution

Based in China facilities with FDA registration and ISO

13485:2016 certificated, Orantech offers wide options to

meet your specific requirements and support an extensive

range of customized product solution in high or low

volumes efficiently, from components and kits to design

and certification.

Injection Molding/Over

Molding/Insert Molding

Cable & Wire Harness

Assembly

Ultrasonic

Welding/Crimping/Soldering/Adhesive Bonding

Custom

Tooling for precise performance in production

In-process

Inspections to ensure superior quality build in

workmanship

Process Development/Fully Validation

(IQ/OQ/PQ)

Laser Marking and Labeling

Lot

Control and Traceability

Supply chain

Medical device manufacturing requires continuous

optimization of innovation, risk management, supply, and

cost. Safety, quality, on-time delivery, continual

improvement, and maintaining the effectiveness of our

business management system is achieved through

teamwork.

Purchasing Controls

Design and Change Controls

Value Analysis &

Value Engineering Process

Schedule Production

Vendor-managed Inventory

Measure Logistics

and Service Excellence

Process Validation/MSA

executed at vendor facility

Quality assurance

At Orantech, Quality Assurance is a critical part of the

process. Compliance, Customer satisfaction, and meeting

all applicable requirements is the responsibility and

commitment of all Orantech employees.

FDA

Registered Facility

ISO:13485:2016 Certified

CE

Mark and FDA 510K approved products

Compliant with

applicable National and International Regulations

In house Testing and Verification Process

Qualification and Validation

In house TMV

(GR&R) Process

Protocol and Report Approval

Continuous

Improvement through Plan-Do-Check-Act Methodology

Contract manufacturing services

When you partner with Orantech, you’re connected to an expert manufacturer with diverse resources to manufacture your product at any scale required. We incorporate a formalized program for tracking customer documents, revisions, and updates to ensure customer-authorized change control and unit-to-unit repeatability between production runs.

Manufacturing Process Definitions

- DFM = Design for Manufacturing

- MVP = Minimum Viable Product

- PFMEA = Process Failure Mode Effects Analysis

- SOP = Standard Operating Procedure

- QCP = Quality Control Plan

- DVT = Design Validation Test

- DOE = Design of Experiments

- PV = Process Validation

- IQ = Installation Qualification

- OQ = Operational Qualification

- PQ = Performance Qualification

- TMV = Test Method Validation

- FAI = First Article Inspection

- ECN = Engineering Change Notice

- PCN = Product Change Notification